- today

- label News

- favorite 0 likes

- remove_red_eye 88 views

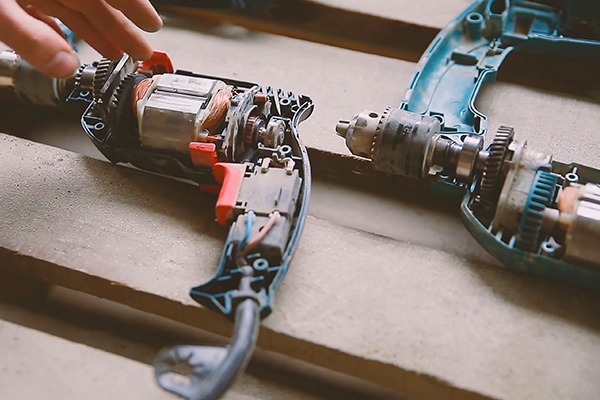

Electric motors are essential in industry and at home. One of their most important components is the brushes, which are responsible for transmitting current. Understanding the types of brushes and their applications helps improve efficiency and extend the motor's lifespan.

What are brushes for electric motors?

Brushes are conductive components that maintain contact between the rotor and stator. They facilitate the flow of electrical current and ensure the motor's proper functioning. Their material, shape, and resistance determine their performance and durability.

Carbon brushes

Carbon brushes are the most commonly used in universal and DC motors. They offer good conductivity and wear resistance. They also provide quiet and stable operation.

These brushes are suitable for power tools, household appliances, and small industrial motors. Although they wear out over time, their low cost and easy replacement make them very popular.

Graphite brushes

Graphite is a self-lubricating material that reduces friction and heat. Graphite brushes are notable for their long lifespan and excellent performance in high-power motors.

They are used in energy-intensive equipment such as elevators, cranes, and heavy machinery. They also withstand variable loads well and offer stable contact.

Carbon-graphite brushes

The carbon-graphite blend combines the best of both materials. This type of brush balances the conductivity of carbon with the resistance of graphite.

They are used in continuous-use motors, electric generators, and industrial machinery. Thanks to their versatility, they guarantee a good balance between service life and stability.

Metal brushes

Metal brushes are made of copper, bronze, or other metals. They are ideal for applications requiring high conductivity and low electrical resistance.

They are installed in low-voltage DC motors and lightly loaded equipment. Although they wear more quickly, they ensure firm and efficient contact.

Electrographic brushes

These brushes are made with special materials that reduce sparking and improve stability. They are widely used in electronic systems and devices requiring precision.

Their main advantage is the reduction of electrical interference and increased motor safety.

Factors to consider when choosing wiper blades

When selecting brushes for an electric motor, several aspects should be considered:

- Motor type and required power.

- Operating conditions and temperature.

- Allowable friction level.

- Durability and maintenance costs.

A correct selection improves efficiency and prevents premature failure.

Maintenance of the brushes

Proper brush care prolongs motor life. It's important to check them periodically and replace them when worn. It's also recommended to clean the commutator and prevent carbon dust buildup.

Proper maintenance reduces the risk of sparks, overheating, and loss of performance.

Conclusion

Different types of electric motor brushes perform specific functions depending on the material and application. Choosing the right option ensures an efficient, long-lasting, and safe motor. Keeping them in good condition is key to optimal performance.