- today

- perm_identity Chapman, Stephen J.

- label News

- favorite 0 likes

- remove_red_eye 384 views

Etymology

For certain types of electric motors or generators to function, the coils of the rotor must be connected to complete an electrical circuit. Originally this was accomplished by affixing a copper or brass commutator or 'slip ring' to the shaft, with springs pressing braided copper wire 'brushes' onto the slip rings or commutator which conduct the current. Such brushes arced and even welded as the commutator rotated, because the brush short-circuited adjacent segments.

The cure was the introduction of 'high resistance brushes' made from graphite (sometimes with added copper). Although the resistance was of the order of tens of milliohms, they were high resistance enough to provide a gradual shift of current from one commutator segment to the next.

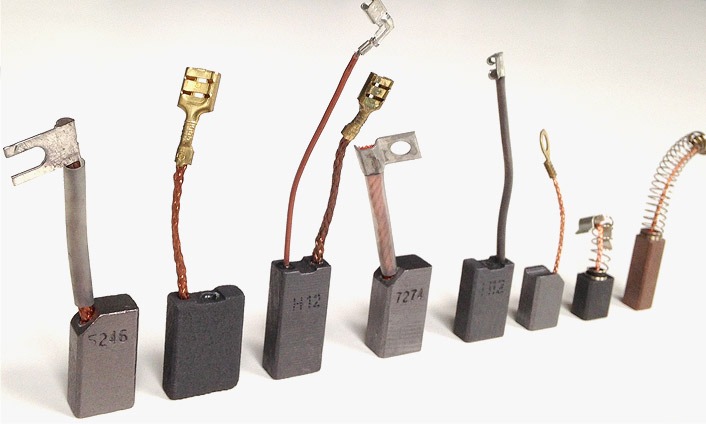

Carbon brushes are available in four main grade categories: carbon graphite, electrographitic, graphite, and metal graphite.[3] The term brush remains in use. Since the brushes wear out, they can be replaced in products intended to allow maintenance.

During World War II, high–altitude aircraft generators had very rapid brush wear, requiring reformulated brush compounds for acceptable life.

Metal fiber brushes are currently being developed.[4] They may have advantages over current brush technology, but have not yet seen wide implementation.